Types of Kayak Materials

Ranging from casual recreational crafts to sleek racers to bomb-proof whitewater and other rec’ boats, the options for the types of materials and hi-tech proprietary processes used to build a particular model are widespread among manufacturers. Learning the make-up and specifications of each of these boat material choices is akin to reading the opening chapter in a chemical engineering 101 text book.

Kayak building processes can be broken down by the different types of construction materials used to form the boat, either in its entirety, or by creating a deck and a hull and joining the two pieces together: wood, composite glass (fiber, aramid, graphite), rotomold, thermoform, and others (inflatables, folding). Also, the pros and cons of each of these materials should be considered carefully when deciding on what kayak to purchase. That process alone requires you to determine what kind of use, and abuse, you expect your kayak to handle. That, in turn, will weigh critically upon which material will perform best within that water venue.

Here’s a brief overview of each of these materials/construction methods and the pros/cons of each type:

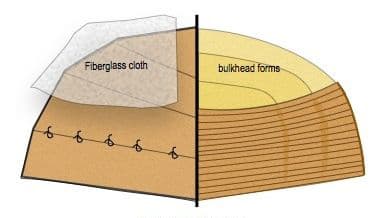

Wooden Kayaks

Mostly “Do-It-Yourself” built using the stitch-and-glue process, or strip-built boats. Design possibilities with the strip-builts are virtually endless while the kits available for stitch/glue models mean that you don’t have to be an advanced wood-worker to build one. In fact, you can get someone to do it for you.

Wooden deck/hulled boats are typically covered in fiberglass, resin and varnish to protect the wood layer - making them as durable as most any synthetic composite construction and at the lighter end of the weight scale among other boat fabrication materials.

50 years of lightweight, maneuverable, high-performing kayaks.

Check out this interview with Tom Keane, Eddyline Kayaks Co-Owner, on their journey!

Pros/Cons of Wooden Kayaks

For looks, the strip-built boats are a thing of beauty. This process allows for a nearly endless array of design options, too. The fiberglass and varnish finish makes a wooden kayak as strong as a composite boat at a much lower cost and perhaps 25% or more lighter (upwards of 20 pounds in some cases) than their fiberglass counterparts. Some consider wooden kayaks to have strength comparable to Kevlar/Graphite composites.

The challenge with wood boats is that you need the skills to build it yourself or hire someone (and that’s gonna cost you!). However, the Stitch-and-Glue models require less woodworking skills and produce a seaworthy craft that you built yourself.

Wood and rapids/rock gardens are not the friendliest of river partners so paddling should be limited to ‘softer’ rivers and waterways.

________

Composite/Glass Construction Kayaks

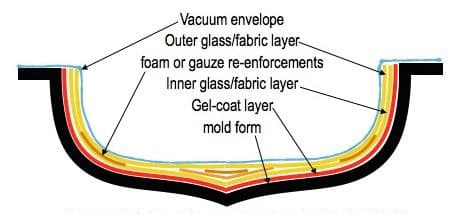

Since construction techniques are basically the same, boats made of what we commonly know as “fiberglass”, those made of aramid fabric (think Kevlar™) and graphite fibers, are all variations of synthetic fabric construction. Built by layering these fabrics either upon themselves or blended with others, they are then applied to a mold. Fiberglass boat molds include an outer layer of colored gel-coating that will form the surface layer of the finished kayak.

Foams panels and/or gauze are sometimes added for reinforcement in the deck and hull. The entire series of layers in the mold are vacuum bagged and allowed to cure to form either a deck or hull section separately. Those two ‘halves’ are then joined together to form the complete kayak.

Pros/Cons of Composite/glass Kayaks

Fast and responsive! The stiffness of the hull makes these the swiftest of the kayak construction types. Hulls are durable, except against sharp, direct impact hits and inevitable scratches that are usually minute and don’t affect the speed of the hull. Combining layers (fiberglass with graphite) gives you several strength/weight options to consider.

Of the three options: fiberglass, aramid/Kevlar or graphite, all are lighter than rotomolds and graphite is the lightest among the fabric options - and the most expensive. Expect to pay significantly more for all the pounds you’ll drop by going from fiberglass to graphite.

Similar to wooden boats, composites are fairly easy to repair in the field, too.

View all Composite/Glass kayaks

________

Rotomolded Kayaks

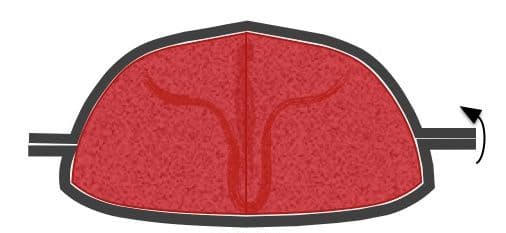

Plastic (polyethylene) powder is poured into a mold, heated and rotated to form a complete, one-piece kayak. Boats are made mostly out of a linear-based molecular structure while others are made from cross-linked poly molecules.

Pros/Cons of Rotomolded Kayaks

These are the least expensive but the heaviest boats among your options. The quality of the plastic used in their construction will affect the weight somewhat, and also the price. Expect the big hogs sold at discount houses to be beasts when it comes to weight as well as trying to wrestle them through the water. Rotomolds aren’t as fine-lined as other options, but some are nearly comparable in performance; they will weigh more, while costing significantly less.

Roto’s are resilient boats, excellent for rocky waterways, taking a rebound with little negative affect. That said, scratches leave minute fuzzies and curl-outs along the hull (affecting speed) and should you puncture or rupture the hull, repairs can be a real problem. Rotomolds are also damaged by exposure to UV and require that you apply protective coatings to the deck and hull.

This type of plastic boat also tends to “oil can” - a depression in the hull or deck area caused by excessive pressure or sag due to the softening of the plastic from extended exposure to the sun or other heat sources - or even being secured too tightly on a narrow, hard roof/storage rack. Most of the time, these depressions will diminish or disappear when brought away from the sun/heat or other stress. Otherwise there are processes one can use to bring the shape back.

________

Thermoform Kayaks

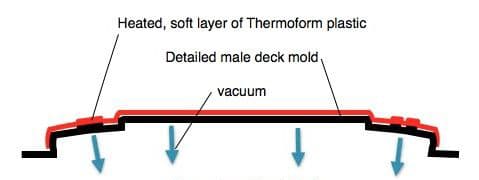

A sheet of ABS (like a plastic alloy with styrene) with a top layer of acrylic is heated and then drawn down onto a mold (as opposed to forming inside the mold as are powered/pellet plastics) to create both hull and deck in separate operations that are then joined together in a process similar to fiber composite boats.

Pros/Cons of Thermoform Kayaks

Imagine a kayak nearly as light as a composite, with the durability close to that of a rotomold and at a price floating towards the lower end between the two - and a thermoform kayak should come into mental view. The bright, lustrous shine of the deck/hull and the numerous color choices make a thermoform boat a popular choice for many paddlers.

Thermoform boats usually have UV protection in the outer layer. This form of plastic tends to deteriorate over an extended period of time, but unlike other plastic boats, thermoforms are generally recyclable.

________

Inflatables/folding Kayaks

Briefly, inflatables are just that - kayak-socks made from strong poly’-based fabric to provide shape and rigidity throughout the boat. Drop-stitch construction enables higher inflation pressures that in turn give the hull/deck their strength integrity. Folding boats are typically canvas or nylon skins stretched over wood or aluminum frames. New technology has also enabled designers to use interlocking panels and fold patterns to create strong folding kayaks.

Pros/Cons of Inflatables/folding Kayaks

Popular among many paddlers who like to carry their boat with them on when the travel, and/or those who have little storage space for a full size/length kayak. Material-size, the nylon decks and hypalon hulls of the class wood or aluminum-framed folding boats are nearly as bombproof as their hard-shell cousins, and typically come with their own repair kits. Other forms of folding boats have also entered the “folding” kayak market and offer lightweight traveling/storing options as well.

Folding kayaks tend to cost more than their rigid fiberglass counterparts. Modern folding kayaks are as sleek and nearly as rigid as hardshells. They are just slightly more susceptible to punctures. They also require more maintenance because of all the framework components. Another point to consider is how often do you intend to paddle? Do you leave the boat assembled for daily or weekly use, or do you put it together and take it back apart after each occasional paddle? How often do you intend to travel with it?

Inflatables also have the advantage of travel-worthiness and storage options. These tend to come in a broad range of sophisticated designs and complexity - from inexpensive tubes held together into the shape of a kayak/canoe to baffled air bladders and fused chambers that provide strength and shape integrity when inflated.

Of course, since the rigidity and ultimate seaworthiness of an inflated craft is totally dependent upon air, punctures are critically serious. Most inflatables tend to be beamy, too, limiting their performance to narrower applications. Despite their beaminess, they don’t always have much room for gear stowage.

________

How Each Material Is Formed Into A Kayak:

Wood:

Using wood bulkheads to make the entire kayak form, panels of wood (L) arre “stitched” together with wire and then glued; (R) a series of strips are secured and glues in place to for a strip-built kayak. Fiberglass cloth and resin are then used to cover the boat, followed by a coat of marine varnish.

________

Composite/"Glass":

Fiberglass, Aramid (Kevlar) or Graphite kayaks (deck and hull) are formed from layers of fabric and strengthening material, resin and gelcoat, then vacuum cured a mold.

________

Rotomold:

Polyethylene pellets/powder within a kayak mold are heated and rotated to create a plastic kayak shell in one piece.

________

Thermoform:

Deck and hull thermoformed separately using heated sheet of plastic laid onto detailed male deck/hull mold and pulled down onto form using vacuum suction.

________

Final Notes

Each boat material, and the subsequent designs to which it’s applied, affects the ultimate handling/functioning capabilities of the kayak. Selecting what material your boat should be made from can best be determined once you have a good sense of how you plan to use it - quiet pond or paddling inshore calm waters, more responsiveness or more challenging and demanding sea treks…and even how/where you plan to store it? And even once you narrow it down to a few specifics, there still a broad market from which to choose the “right” boat.

Perhaps the biggest difference and one that you need to consider, especially if you intend to use your kayak for extended trips, is how easy it is to do field fixes on your boat, and in the case of serious breaches in the hull or deck - more structurally sound repairs that maintain the integrity of your boat. Duct tape bandages might seal a hole on any of these materials, but a secure, permanent repair might mean plastic welding or finding the right adhesives and paints that will even stick to the surface in the first place. I’ll be covering repair options for each of these materials in an upcoming article.

Another point to consider, especially when costs are a factor, is what is your commitment to kayaking? If you intend to enjoy leisurely recreational paddles around the cabin lake or city pond, an inexpensive recreational kayak may be perfect for you. If, however you intend to hone your skills, pursue your passion and really want to be a competent paddler, you may want to buy up from your initial thoughts on a “beginner” boat and think about your options (cost vs. weight, durability and performance) over the course of your learning curve. Knowing the pros/cons and other characteristics of the kayak construction material options can help you make a lasting positive decision on your choice of boat.

Be safe, have fun out there!

Related Articles

Remember when you bought your first car? Or maybe it was a bike. You may have chosen it for its color,…

Ever wonder what exactly the weight capacity of a board was for? Turns out it's for the performance of…

Adhering to the fundamental safety rule that a lifejacket should always be worn when out on the…

Canoes and sit-inside kayaks have been used for fishing by many of our ancestors. But it seems that once…