How It's Made - Aluminum Canoes

How is an aluminum canoe made?

Check out this step-by-step breakdown from stretching the steel to testing the rivets under pressure to make an aluminum canoe.

-

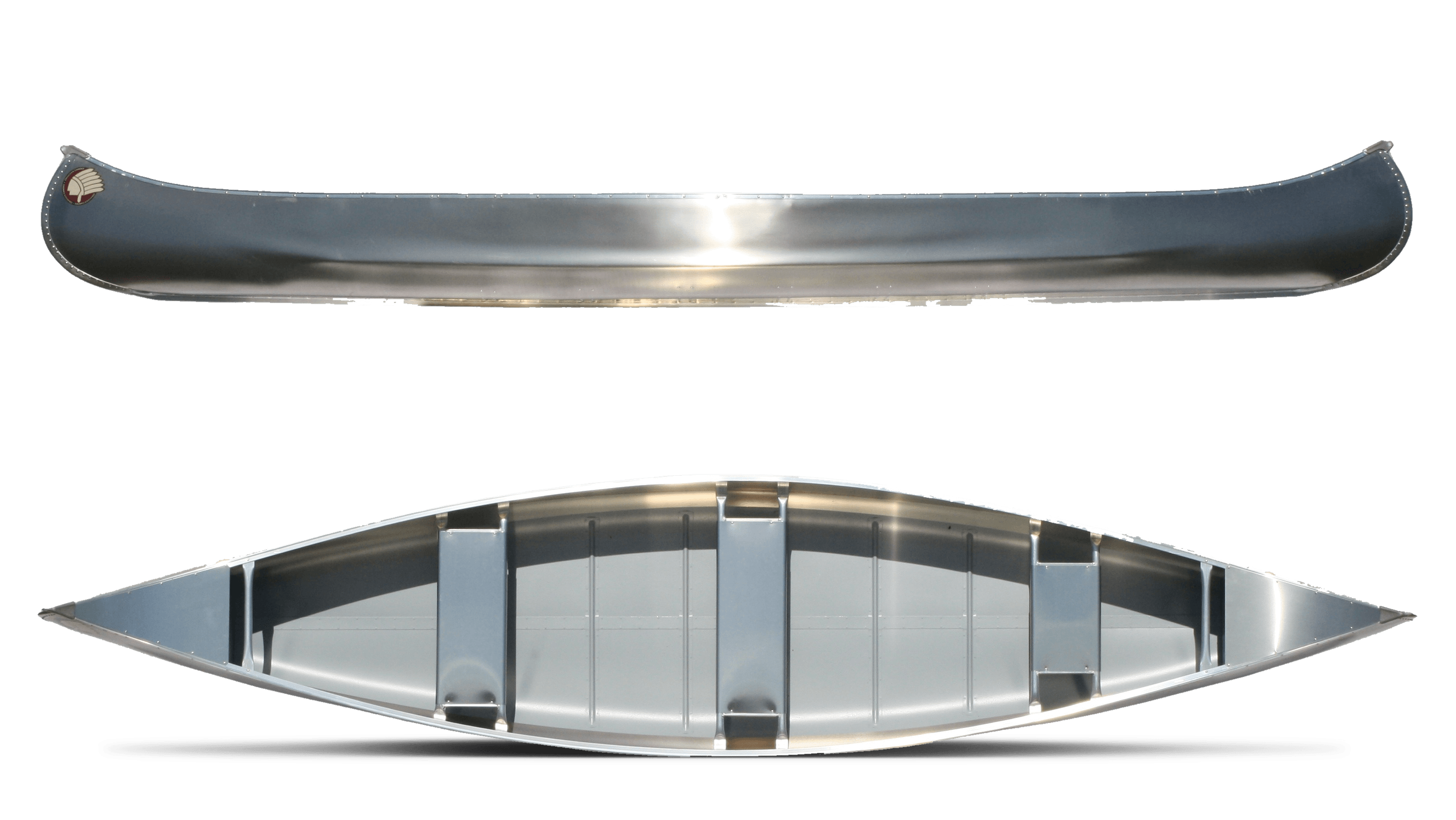

When World War II ended, an American manufacturer of fighter jets needed to land new business. The factory employed the same stretched aluminum process used for shaping aircraft wings and came up with an aluminum canoe. The aluminum canoe is designed for a peaceful day at the lake. Among water craft, the aluminum canoe is the strong silent type. It resists breaking and cracking when it comes up against a rock or any other underwater object. This is one invention that's unlikely to sink into oblivion. Aluminum itself is too soft for canoe construction so metals like magnesium, nickel and silicon have been added to give it the needed strength.

~Get the BWCAW Tee~

With over 1,090,000 acres of wilderness area, the BWCAW is a paddler's paradise.

Aluminum Canoe Construction Process

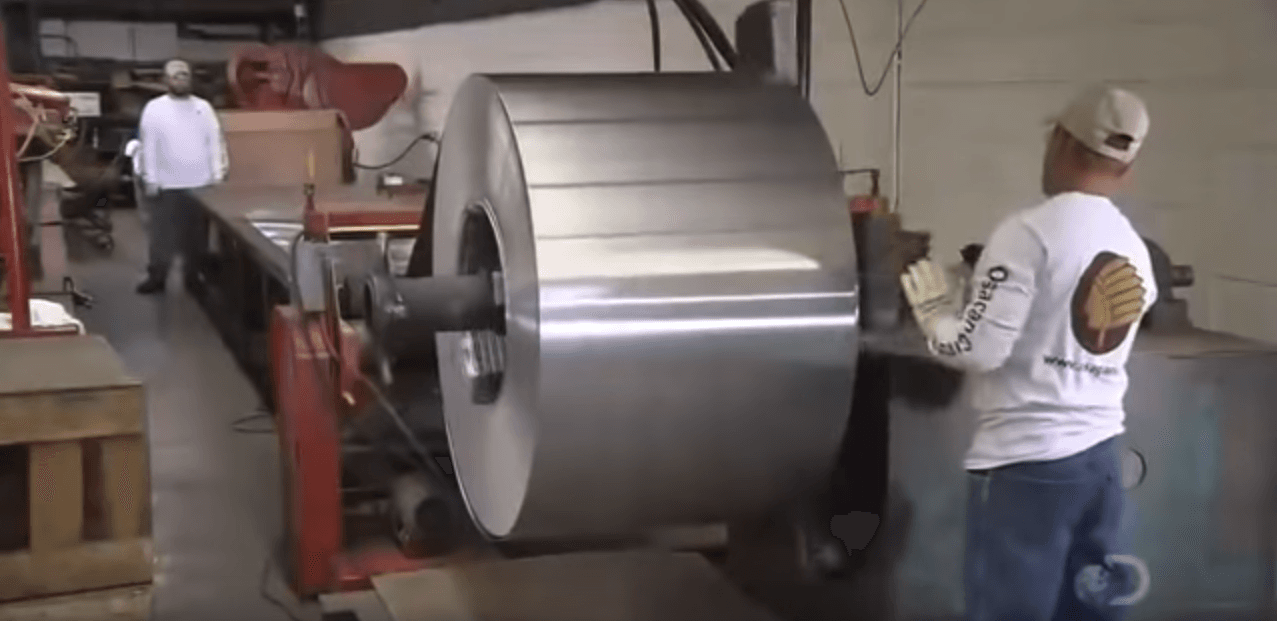

Factory employees unwind the aluminum alloy onto a work table. Using electric shears they cut it to length. They lift the metal sheet onto a mold of part of the canoe hull, they clamp the metal to a hydraulic system and activate it it falls and stretches the aluminum alloy sheet to the mold and it conforms to its shape. The molded sheet needs trimming so they transfer it to a work table and place a template over the contoured section. They clamp it into place with a scribe and one of the workers etches the pattern onto the molded aluminum. The team then transfers the aluminum sheet to a jig and cuts out the pattern following the etched outline. They shape and cut a second part exactly like the first. The two symmetrical halves will form the hull of the aluminum canoe.

They bake the hull halves at 200 degrees Celsius for eight hours. The heat strengthens the aluminum and adds rigidity to it. Out of the oven now, a member of the team aligns two halves and it's a perfect match, so he now lowers a large clamp once in place. He turns a crank to pull the two parts of the aluminum canoe together tightly clamped.

He welds the two parts along the bottom. This joins them with a watertight seam with hand clamps, he tacked the two rounded ends together and welds here. He links the end welds to the one on the bottom and the result is one continuous leak proof weld from bow to stern. Next, the team positions an aluminum keel along the bottom seam, they reinforce it from the inside with a t-bar, they drive rivets through the t-bar hull and keel to secure the assembly and they install substantial aluminum guards on the bow and stern using rivets to secure them. These guards will protect the end welds. They brace the base of the canoe from the inside with 6 aluminum ribs welded and riveted, and with a good support structure this aluminum canoe has really taken shape. They equip the rim of the canoe with aluminum gunnels, pounding them with a rubber mallet to improve the fit.

Then a worker rolls non-skid paint on the inside so it won't become slick when wet. They bring in incandescent heat lamps and the paint dries quickly in the warm glow after just 30 minutes. The paint is dry then it's time to see if it'll float.

They transfer the aluminum canoe to a tank of water they clamp a bar across the canoe to apply 450 kilograms of pressure, more than the weight of two people. They check for leaks especially around the rivets. The cross bars and bench seating complete the fabrication. There's one last bit of business and that's the company insignia. This aluminum canoe is now ready for recreation. 10 hours in the making and the fun has only just begun!

Special thanks to Osagian Canoes for the glimpse into their world of manufacturing. For more, please check out current aluminum canoes and read aluminum canoe reviews in the paddling.com gear guide!

Aluminum Canoe Gear Guide

Check out some aluminum canoes below or head over to the canoe gear guide to see them all!

Related Articles

Remember when you bought your first car? Or maybe it was a bike. You may have chosen it for its color,…

The summer weather may be drawing to a close, but this year's paddling season is far from over! As we…

Kayakers from antiquity utilized deck space for storing gear, namely hunting and fishing accessories.…

Canoes and sit-inside kayaks have been used for fishing by many of our ancestors. But it seems that once…